产品展厅

|

Vespel CR-6110 PI DuPont 杜邦

- 品牌:DuPont 杜邦

- 型号:板、棒、管、方块、长条、圆盘、环、圆球和定制机加工制件

- 价格: ¥13.7/千克

- 发布日期: 2024-08-09

- 更新日期: 2025-12-26

产品详请

| 品牌 | DuPont 杜邦 |

| 货号 | |

| 用途 | 杜邦? Vespel? CR-6110 形状是最新的碳纤维填充热塑性含氟聚合物,在腐蚀性的湿化学/等离子体条件和高温下表现出出色的性能。客户报告说,在晶圆清洗和光刻胶剥离操作中改用 Vespel? CR-6110 后,预防性维护周期得到了改善。它还在平板显示器应用中表现出良好的抗紫外线 (UV) 性能。在干等离子体应用中,Vespel? CR-6110 已被用作隔热材料和轴承。 |

| 牌号 | Vespel CR-6110 |

| 型号 | Vespel CR-6110 |

| 品名 | 聚酰亚胺类 |

| 包装规格 | 板、棒、管、方块、长条、圆盘、环、圆球和定制机加工制件 |

| 外形尺寸 | 板、棒、管、方块、长条、圆盘、环、圆球和定制机加工制件 |

| 厂家 | DuPont 杜邦 |

| 是否进口 |

在 条件下值得信赖

Vespel® 部件和型材适用于恶劣的工业操作环境

温度、高摩擦和重负荷?自 1965 年以来,在恶劣的条件下,Vespel® 的性能表现优于其他工程材料。

诸如航空航天部件,半导体加工,汽车制造和能源生产等要求苛刻的应用依靠 Vespel® 零件来保证其设备运行。

Vespel®聚酰亚胺材料可在低温至高温下连续运行; 在润滑或未润滑的环境中,在高 PV 下的低磨损和低摩擦; 优异的抗蠕变,高强度和抗冲击性; 出色的尺寸稳定性; 低热膨胀系数; 以及易加工性。

Vespel® 使零件重量更轻不仅切实可行,而且在许多情况下优于通用金属,陶瓷和其他工程聚合物,例如 PEEK(聚醚醚酮)和 PAI(聚酰胺-酰亚胺) )。

在亚洲、欧洲和美洲的设计中心,杜邦技术人员与客户一起合作,将材料科学与设计相结合,以生产高性能零件并保持生产平稳运行。

Vespel® 部件与型材(无论定制的还是常规规格)都经过测试,已在 苛刻的应用中经过测试并证明可靠。它们有板、棒、管、方块、长条、圆盘、环、圆球和定制机加工制件。[

用途

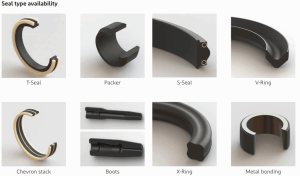

- 轴承、衬套、绝缘件、密封件、止推垫片和耐磨环

- 耐磨垫、耐磨条和管夹

- 热塑性注塑、装配和复合部件

- 测试插座和晶圆导轨

- 玻璃夹持技术

- 离心泵中的耐磨部件

- 碳氢化合物、化学品和给水泵

- 饮用水应用

优势

- 低蠕变和低释气

- 轻质但能承受高负荷

- 耐化学性、耐电气、耐磨损和耐热性

- 强度、刚性和尺寸稳定性

- 易于机加工,可加工至非常紧密的公差

- 在极限真空、辐射、氧气相容性、低温条件以及暴露于火焰的情况下行之有效

- 制造成本低于陶瓷

Vespel is the trademark of a range of durable high-performance polyimide-based plastics made by DuPont.[1][2]

Characteristics and applications

[edit]

Vespel is mostly used in aerospace, semiconductor, and transportation technology. It combines heat resistance, lubricity, dimensional stability, chemical resistance, and creep resistance, and can be used in hostile and extreme environmental conditions.

Unlike most plastics,[3] it does not produce significant outgassing even at high temperatures, which makes it useful for lightweight heat shields and crucible support. It also performs well in vacuum applications,[4] down to extremely low cryogenic temperatures. However, Vespel tends to absorb a small amount of water, resulting in longer pump time while placed in a vacuum.

Although there are polymers surpassing polyimide in each of these properties, the combination of them is the main advantage of Vespel.

Thermophysical properties

[edit]

Vespel is commonly used as a thermal conductivity reference material for testing thermal insulators, because of high reproducibility and consistency of its thermophysical properties. For example, it can withstand repeated heating up to 300 °C without altering its thermal and mechanical properties.[citation needed] Extensive tables of measured thermal diffusivity, specific heat capacity, and derived density, all as functions of temperature, have been published.[citation needed]

Magnetic properties

[edit]

Vespel is used in high-resolution probes for NMR spectroscopy because its volume magnetic susceptibility (?9.02 ± 0.25×10?6 for Vespel SP-1 at 21.8 °C[5]) is close to that of water at room temperature (?9.03×10?6 at 20 °C [6]) Negative values indicate that both substances are diamagnetic. Matching volume magnetic susceptibilities of materials surrounding NMR sample to that of the solvent can reduce susceptibility broadening of magnetic resonance lines.

Processing for manufacturing applications

[edit]

Vespel can be processed by direct forming (DF) and isostatic molding (basic shapes – plates, rods and tubes). For prototype quantities, basic shapes are typically used for cost efficiency since tooling is quite expensive for DF parts. For large scale CNC production, DF parts are often used to reduce per part costs, at the expense of material properties which are inferior to those of isostatically produced basic shapes.[7]

Types

[edit]

For different applications, special formulations are blended/compounded. Shapes are produced by three standard processes:

compression molding (for plates and rings);

isostatic molding (for rods); and

direct forming (for small size parts produced in large volumes).

Direct-formed parts have lower performance characteristics than parts that have been machined from compression-molded or isostatic shapes. Isostatic shapes have isotropic physical properties, whereas direct formed and compression molded shapes exhibit anisotropic physical properties.

Some examples of standard polyimide compounds are:

SP-1 virgin polyimideprovides operating temperatures from cryogenic to 300 °C (570 °F), high plasma resistance, as well as a UL rating for minimal electrical and thermal conductivity. This is the unfilled base polyimide resin. It also provides high physical strength and maximal elongation, and the best electrical and thermal insulation values. Example: Vespel SP-1.15% graphite by weight, SP-21added to the base resin for increased wear resistance and reduced friction in applications such as plain bearings, thrust washers, seal rings, slide blocks and other wear applications. This compound has the best mechanical properties of the graphite-filled grades, but lower than the virgin grade. Example: Vespel SP-21.40% graphite by weight, SP-22for enhanced wear resistance, lower friction, improved dimensional stability (low coefficient of thermal expansion), and stability against oxidation. Example: Vespel SP-22.10% PTFE and 15% graphite by weight, SP-211added to the base resin for the lowest coefficient of friction over a wide range of operating conditions. It also has excellent wear resistance up to 149 °C (300 °F). Typical applications include sliding or linear bearings as well as many wear and friction uses listed above. Example: Vespel SP-211.15% moly-filled (molybdenum disulfide solid lubricant), SP-3for wear and friction resistance in vacuum and other moisture-free environments where graphite actually becomes abrasive. Typical applications include seals, plain bearings, gears, and other wear surfaces in outer space, ultra-high vacuum or dry gas applications. Example: Vespel SP-3.

Material properties data

[edit]

Material properties of Vespel[8] (produced by isostatic molding and machining)

Property Units Test

condition SP-1

(unfilled) SP-21

(15% graphite) SP-22

(40% graphite) SP-211

(10% PTFE,

15% graphite) SP-3

(15% MoS

2)

Specific gravity dimensionless 1.43 1.51 1.65 1.55 1.60

Thermal expansion

coefficient 10?6/K 211–296 K 45 34 27 [9]

296–573 K 54 49 38 54 52

Thermal conductivity W/mK at 313 K 0.35 0.87 1.73 0.76 0.47

Volume resistivity Ω·m at 296 K 1014–1015 1012–1013

Dielectric constant dimensionless at 100 Hz 3.62 13.53

at 10 kHz 3.64 13.28

at 1 MHz 3.55 13.90

Vespel® 提供低摩擦和耐磨性,使发动机部件性能更好

对于需要耐用、持久性能的发动机应用,杜邦™ Vespel® 部件具有高尺寸稳定性,即使在润滑不良或具有高 PV 限制的干燥环境中也表现出色。

Vespel® 能够在高温下连续运行,具有低摩擦和低磨损的特点,是用于发动机部件的 材料,包括:

曲轴止推垫圈

同步带张紧器衬套

V V T(可变气门正时)密封环

正时链导轨

此外,Vespel® 还具有出色的耐发动机油性。